Phonograph Self Help

Maison Robert’s Guide to Precision Lubrication

Welcome to Our Shop

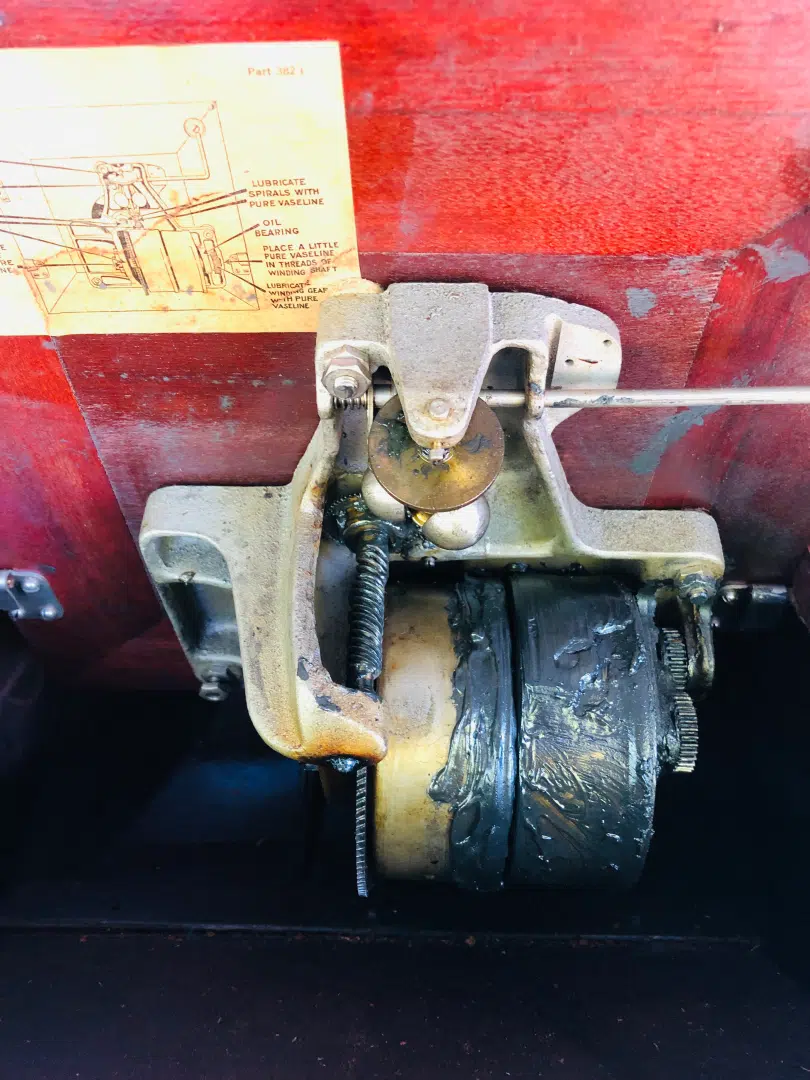

Why Grease on Victrola External Gearing Is a Misguided Shortcut

Precision Lubrication: Why Your Victrola Demands More Than Grease

Your Victrola’s external gearing is a triumph of robust, cleverly balanced engineering but it doesn’t thrive under a blanket of heavy grease. At first glance, thick axle or chassis grease seems advantageous: it clings tenaciously, repels moisture, and promises long “service-free” intervals. Those apparent perks come at the cost of dragging down your mechanism, sapping vital spring energy into heat, and trapping abrasive particles in every tooth.

Did you know? A single drop of ISO 32–46 cSt light machine oil can outlast a glob of axle grease without the drag or messy build up.

Maison Robert experts take a different path. A whisper thin film of light oil on gears provides full film hydrodynamic lubrication (that’s when oil actually floats gear teeth apart) for silent, efficient power transfer. Boundary grade PTFE enhanced moly grease (for surfaces that must handle metal-to-metal contact safely) goes only on larger, long wind springs. Embrace precision, and you’ll enjoy smoother start-ups, predictable maintenance, and a Victrola that spins as brilliantly as its inventors intended.

Victrola external gears operate at low speeds and light loads. They need a thin, stable lubricant film..not a thick, sticky grease that chokes motion, traps grit, and wastes spring energy.

Unpacking Common Lubrication Habits

We often see machines come into our shop that have been cared for with some common, yet sometimes misguided, lubrication practices. You might recognize some of these:

- Generously applying heavy grease (like NLGI #2–3 chassis or axle grease) to every exposed tooth and pivot.

- Counting on grease’s “set-and-forget” reputation to keep service calls to a minimum.

- Assuming that a heavier lubricant always means less wear or better protection.

- Using lubrication to quiet noisy gears, which, while seemingly helpful, can sometimes temporarily mask deeper issues like wear or misalignment.

- Opting for a single lubricant solution for all components, treating gears and delicate springs the same.

While the idea of a simple, one-size-fits-all approach to lubrication certainly sounds appealing and easy, our experience has shown us that this shortcut can often lead to unexpected challenges down the road. Our aim is always to help your machines run their best, and that starts with understanding the nuances of proper care.

How We Believe It Backfires

Here’s a look at some of the unintended consequences:

- Suppressed Oil Film: That heavy grease, especially at lower speeds (under 100 rpm), often can’t flow quickly enough to create a continuous, protective cushion between moving parts.

- Boundary Lubrication (Metal-on-Metal): Without that crucial oil film, gear teeth can actually rub together instead of floating on a lubricant. This dramatically increases friction and wear.

- Elevated Drag: The soap-based thickeners in grease can behave like a semi-solid plug. This means every turn resists motion, converting valuable torque into unwanted heat.

- Abrasive Debris Trapping: Those thickener fibers in grease are excellent at snagging dust, oxidized metal particles, and even fabric fibers. These trapped contaminants then act like tiny grinding agents with every rotation, accelerating wear and pitting.

- Oxidation and Hardening: Over time, grease can oxidize, turning into a sticky, varnish-like deposit. This “gum” can seize up delicate pivots and significantly slow down operation.

- Headache for the Next Technician: Dealing with baked-on grease residue is a big job. It often requires strong degreasers, brushes, or even ultrasonic cleaning – all of which add extra labor, cost, and even the risk of damage to your machine.

Did you know? Properly oiled gears, in contrast, are a joy to work with! They simply wipe clean and can often return right back to whisper-quiet operation (assuming no underlying wear or alignment issues).

Why Heavy Grease Forces Boundary Lubrication and Speeds Wear

Even though heavy grease feels “protective,” a Victrola’s slow, delicate gear train can’t use it the way a car or tractor can. Instead of forming a smooth film, the grease often creates the exact conditions that increase friction and wear.

- Grease Can’t Form a Proper Oil Film: At the low speeds a Victrola runs (typically under 100 rpm), heavy grease can’t flow quickly enough to build a continuous hydrodynamic layer. Without that fluid cushion, the tiny high spots on the metal surfaces touch directly, a condition called boundary lubrication.

- Added Drag Instead of Reduced Friction: The soap‑based thickeners in grease behave more like a soft solid than a flowing oil. Inside a small gear train, that thick mass acts like a plug the gears must push through, wasting torque and generating heat.

- Abrasive Debris Gets Trapped: Grease is excellent at grabbing dust, oxidized metal particles, and stray fibers. Once trapped, these contaminants stay in the gear mesh and grind away with every rotation, accelerating pitting and surface fatigue.

- Grease Hardens Into Varnish Over Time: As grease oxidizes, it dries into a sticky, varnish‑like residue. This buildup clings to pivots and gear teeth, slowing the mechanism and increasing friction.

- Creates Extra Work (and Risk) for the Next Technician: Hardened grease often requires strong solvents, brushes, or ultrasonic cleaning to remove. That adds labor, cost, and a small but real risk of damaging delicate parts. Properly oiled gear trains, by contrast, usually wipe clean and return to smooth, quiet operation.

In short, what feels protective at first can quietly drive your gears into a high‑friction, high‑wear state – the inverse of the precision, ease, and longevity a correct light oil is designed to deliver.

Maison Robert’s Precision Lubrication Strategy

Understanding these challenges, our approach at Maison Robert is built on a foundation of precision and thoughtful material selection. Here’s how our lubrication strategy differs from common practices, ensuring your Victrola receives the specialized care it truly deserves:

| Component | Prevailing Method | Maison Robert Method |

|---|---|---|

| External Gears | NLGI #2–3 axle or chassis grease | ISO 32–46 cSt light machine oil |

| Gear Friction | High drag; debris-picking boundary film | Low drag; full hydrodynamic oil film |

| Small Mainsprings | Generic grease, no modifiers | Moly EP grease (NLGI #1–2), boundary protection |

| Large Mainsprings | Same generic grease | Moly EP + 5–10 % Slick 50 PTFE blend |

| Application Style | Flood-coat and rely on capillary flow | Measured drops on teeth; worked-in grease on coils |

The Science Behind Maison Robert’s Choice

Why do these specific choices make such a difference? It all comes down to the fundamental physics of lubrication. Our methods are rooted in these key principles:

- Hydrodynamic vs. Boundary Lubrication: Imagine a thin, flowing river that keeps two boats from touching. That’s similar to how light oil works: it self-spreads to create a continuous, full-film layer that effectively eliminates metal-to-metal contact. This is called hydrodynamic lubrication. In contrast, thick grease, especially at the slow speeds of a Victrola, struggles to form this full film. It often forces boundary lubrication, where the metal surfaces are essentially rubbing against each other, dramatically increasing friction and wear.

- Viscosity and Energy Loss: Think of stirring honey versus water. High-viscosity grease, like honey, inherently resists movement, especially at startup. This resistance means that a significant portion of the spring’s energy is converted into unwanted heat rather than smooth, efficient rotation. A carefully chosen machine oil, with its lower viscosity, allows for smooth torque delivery, ensuring that the beautiful sound of your Victrola isn’t fighting against its own mechanics.

- Debris Management: Grease’s thick, sticky consistency makes it a prime candidate for trapping dust and abrasive fibers, turning them into miniature grinding pastes that continuously damage the gear teeth. Light oil, however, allows these contaminants to remain suspended and, importantly, to be carried out when the surfaces are wiped clean. This keeps the delicate gear teeth consistently clean and precise, contributing to the longevity and smooth operation of your cherished machine.

The Maison Robert Method Delivers

- Lower startup friction and cleaner torque delivery

- Quieter operation with minimal chatter

- Cleaner interior—no greasy drips or trapped debris

- Predictable service intervals (6–12 months)

- Targeted use of PTFE only where springs demand it

Ultimately, we encourage you to abandon the “grease-everything” myth. By carefully matching lubricant properties to each component’s specific needs, we can unlock significantly smoother, more efficient, and longer-lasting performance from your Victrola.

The Maison Robert Difference: Precision for Lasting Performance

At Maison Robert, our goal is always to help your cherished Victrola perform at its absolute best, bringing joy for generations to come. By carefully aligning lubricant properties with each component’s unique requirements, we ensure optimal performance and longevity.

Using light oil on external gears creates a protective hydrodynamic layer, virtually eliminating metal-on-metal contact and minimizing drag. For high-stress springs, we opt for Moly EP grease, selectively enhanced with PTFE only where its unique boundary protection is truly needed, without adding unnecessary bulk.

This precision approach isn’t just about technicalities; it’s about reducing wear, significantly improving efficiency, and ultimately, ensuring your Victrola operates smoothly and reliably for years to come. You can feel confident that with Maison Robert’s care, your machine will not only sound its best but also stand the test of time.

Remember: This list is not exhaustive. If you have any concerns about your machines performance, don’t hesitate to contact us directly on the form below for a diagnosis and free repair quote. We’re passionate about bringing these beautiful machines back to a state of good health!

In home service also available

How It Works

Repair & Restoration

Tell us about what you have, what your requirements are, or vision is for that piece, and we’ll take it from there.

Need A Quote?

Start Here

01

Contact Us For Quote

Reach out via the “start here” link, or call directly if you prefer to. We’ll assess time & cost and send a quote to you.

02

Schedule A Pickup or Dropoff

Once the quote has been accepted, we will arrange a time for you to drop off (no charge), or to pick up (small fee) your item. We also offer onsite repairs in some cases. *Ship to address will be on the quote.

03

Project Complete

We will notify you by email/text that you item is complete, along with an online payment link. If we are dropping off, we will work with you to choose a suitable time for you to receive your item.

You might also like

pres·er·va·tion

“Preservation transcends mere historical custodianship; it’s the silent keeper of our cultural dawn..”

Restore

The goal of vintage restoration is to preserve the original character and integrity of the item. This means using materials and techniques that are as close to the original as possible. Vintage restorers also take care to preserve any unique features or patina that the item may have developed over time.

Refinish

At Maison Robert, we believe that vintage items are treasures that should be cherished. That’s why we take the utmost care in refinishing our vintage pieces, using only the highest quality materials and techniques.

We understand that every vintage item is unique, and we work to preserve its original character and integrity while also improving its appearance and functionality.

Repair

We believe that vintage items have unique value, have a history and character that cannot be replicated, and that should be preserved.

Vintage items are often made with high-quality materials and craftsmanship, and they can last for many many years if they are properly cared for. They made it this far. We also believe that preservation is a way we can show our respect for the past, pay homage, and contribute to creating a more sustainable future.